Unlocking Supply Chain Automation for Growth and Efficiency

At its core, supply chain automation is all about using technology to handle the repetitive, everyday tasks that clog up your logistics, procurement, and inventory workflows. Think of it as replacing endless manual data entry, order processing, and tracking with smart, efficient systems.

The goal is refreshingly simple: let technology do the grunt work so your team can focus on what humans do best—strategy, creative problem-solving, and building relationships.

What Is Supply Chain Automation Really?

Let’s try a simple analogy. Imagine your supply chain is a busy restaurant kitchen. In a manual operation, orders are shouted across the room, tickets get lost, and ingredients run out unexpectedly. The result? Chaos, delays, and unhappy customers.

Now, picture that same kitchen with supply chain automation. It's more like a Michelin-star operation. Digital orders appear instantly on screens, inventory is tracked down to the last olive, and every station works in perfect harmony. That’s the kind of seamless efficiency automation brings to the table.

This shift isn't just a nice-to-have anymore. With customers demanding faster deliveries and global disruptions becoming the norm, manual processes just can't keep up. Automation builds a stronger, more flexible backbone for your entire operation.

From Manual Grind to Smart Systems

At its heart, automation is about freeing your business from the bottlenecks that stifle growth. Instead of your team spending hours manually keying in invoice data or chasing down shipments on carrier websites, software can do it all in a fraction of the time—and without typos.

To see the transformation of common supply chain tasks before and after automation, check out this quick comparison.

A Quick Look at Manual vs Automated Supply Chains

| Task | The Old Manual Way | The New Automated Way |

|---|---|---|

| Invoice Processing | An employee manually types data from a PDF into the accounting system. | Software reads the invoice, extracts the data, and inputs it automatically. |

| Inventory Tracking | Staff conduct periodic, time-consuming physical stock counts. | Barcode scanners and sensors provide real-time inventory levels 24/7. |

| Order Fulfillment | A worker walks through aisles with a paper pick list to find items. | The system sends optimized picking routes directly to a handheld device. |

| Supplier Updates | Emails and phone calls are made to confirm orders or check on status. | Purchase orders and status updates are sent and received automatically. |

The difference is night and day. By handing these rule-based tasks over to technology, you give your team the breathing room to focus on what really drives value: analyzing performance, negotiating better deals, and keeping customers happy.

The Numbers Driving the Shift

The move toward automation isn't just a trend; it's a massive industry shift backed by some serious numbers.

Take Robotic Process Automation (RPA), a key technology in this space. Valued at $2,942.7 million in 2023, its market is expected to grow by a massive 39.9% each year through 2030. It's no wonder that over 70% of supply chain leaders now see RPA as a must-have for cutting down on manual work and costly mistakes.

Ultimately, understanding what automation means is about seeing the bigger picture. It involves tools like warehouse automation software and connecting all the moving parts of your supply chain into one intelligent system—one that can adapt, solve problems, and grow right alongside your business.

The Core Technologies Powering Modern Supply Chains

To really get what supply chain automation is all about, you have to look under the hood at the engines driving it. These aren't just buzzwords; they're practical tools built to handle specific jobs with incredible speed and accuracy. When they work together, they create a powerful system that completely changes how a business operates, shifting it from manual grunt work to intelligent, automated execution.

Think of it like building a high-performance car. You need different parts working in harmony—an engine for raw power, a computer for smart decisions, and sensors for real-time feedback. The world of supply chain automation is no different; its core components are just as distinct and just as vital.

The Digital Workforce and Intelligent Brains

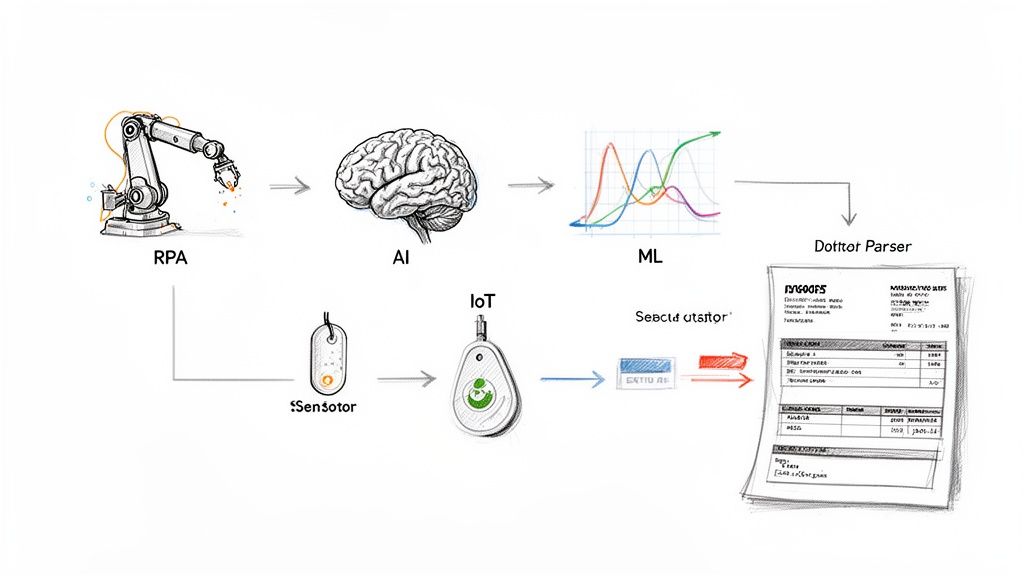

At the most basic level, you have Robotic Process Automation (RPA), which is essentially your digital workforce. These software “bots” are absolute workhorses for the repetitive, rule-based tasks that people find mind-numbing. Imagine a bot that opens an email, downloads an invoice, copies the key data, and pastes it into your accounting system. It can do that all day, every day, without ever making a typo.

RPA is fantastic for those straightforward jobs, but it’s just the starting point. When things get more complex, you bring in Artificial Intelligence (AI) and Machine Learning (ML). If RPA bots are the tireless workers on the assembly line, AI and ML are the strategic brains of the entire operation.

AI doesn't just follow a script; it learns from data to make smart predictions and recommendations. It can sift through past sales figures, weather forecasts, and market trends to forecast future demand with startling accuracy. That's how you avoid running out of stock or getting stuck with a warehouse full of products nobody wants.

These systems get smarter over time, constantly refining their models to optimize logistics and find better delivery routes. This predictive muscle allows a company to stop reacting to problems and start proactively solving them before they even happen.

The Eyes and Ears of Your Operation

While AI provides the brainpower, the Internet of Things (IoT) provides the real-time data it needs to do its job. IoT is simply a network of sensors and smart devices embedded in everything from shipping containers and warehouse shelves to delivery trucks. These sensors are the nervous system of your supply chain, constantly collecting and sending back crucial information.

This non-stop data stream gives you a level of visibility that was once impossible:

- Location Tracking: GPS sensors tell you precisely where a shipment is at any given moment.

- Condition Monitoring: Tiny sensors can monitor temperature and humidity, ensuring sensitive goods like pharmaceuticals or fresh food are kept in perfect condition.

- Inventory Levels: Smart shelves can automatically signal when stock is low, kicking off the reordering process without anyone lifting a finger.

This flow of live information is what lets your AI make smart, context-aware decisions. Without IoT, even the most advanced AI would be working with old data, making it useless in the fast-moving world of a modern supply chain.

The Universal Translator for Business Documents

Finally, none of this works if the data going into the system is a chaotic mess. This is where Intelligent Document Processing (IDP) plays the unsung hero. Supply chains run on a mountain of documents—invoices, purchase orders, bills of lading, you name it. And they all show up in different formats, like PDFs, scanned images, or buried in emails.

To most software, this unstructured data is just gibberish. An IDP platform like DocParseMagic acts as a universal translator. It uses AI to read these documents the same way a person would, instantly identifying and pulling out key details like invoice numbers, line items, and payment totals.

It takes that messy, unstructured information and turns it into clean, organized data that your other systems can actually understand and use. To see just how this works, you can learn more about what is intelligent document processing and how it bridges the critical gap between raw documents and actionable data. This one step is often the key, ensuring your entire automation engine is running on fuel it can trust.

How Automation Actually Changes Day-to-Day Work

The true magic of supply chain automation isn't some high-level, abstract concept. It's about how it fundamentally changes the daily grind for your teams. It’s the difference between constantly putting out fires and proactively steering the ship. Instead of being buried in paperwork, your people can finally focus on what matters: thinking strategically, building better relationships with suppliers, and finding new ways to grow the business.

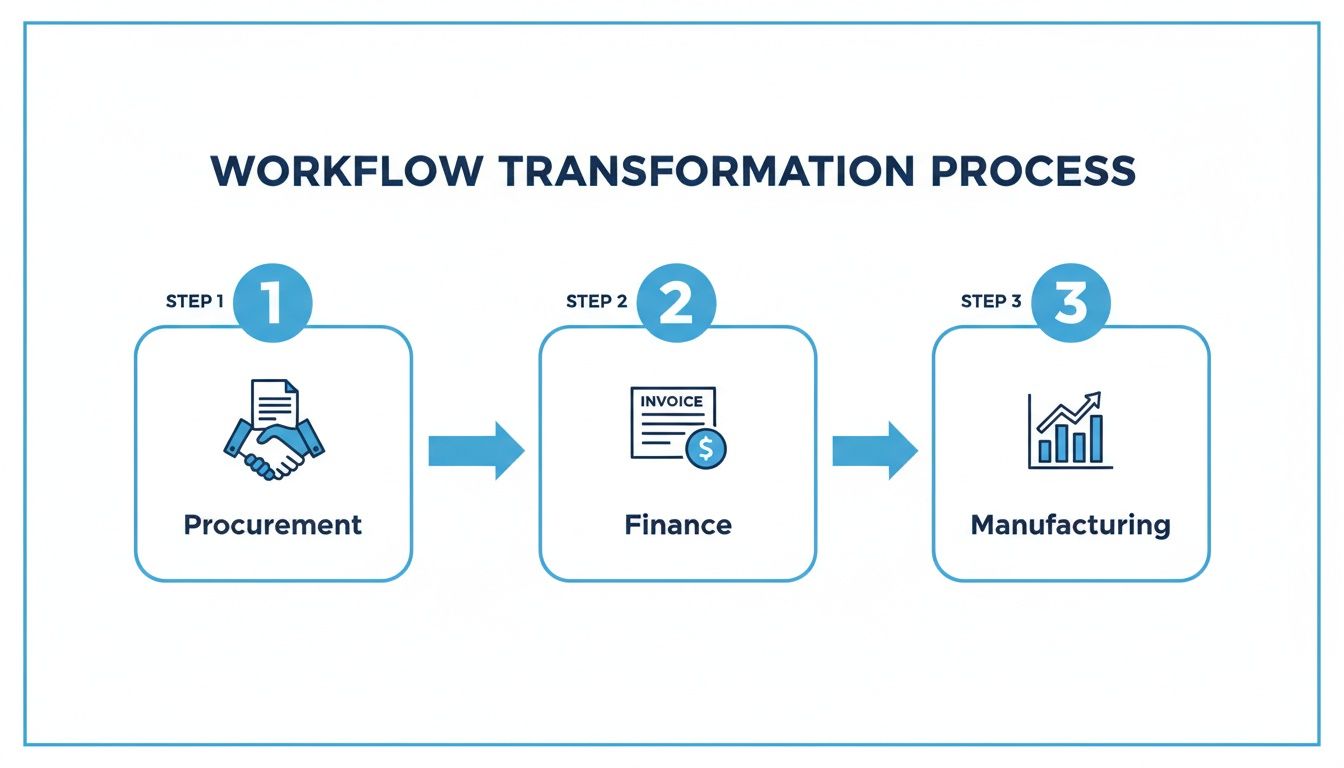

Let’s get practical and look at how this plays out in the real world. We'll explore how automation tackles the common, expensive headaches that plague procurement, finance, and manufacturing teams every day. While each department has its own unique frustrations, the solution usually boils down to a single, powerful idea: let smart technology handle the tedious, repetitive stuff.

Supercharging Procurement From Analysis Paralysis to Action

Picture this: your procurement team needs to source a critical component. The old way involves sending out a bunch of RFPs and then waiting. Days, sometimes weeks, are lost as they manually comb through dozens of PDFs from different vendors. Each one is formatted differently, forcing your team into a copy-and-paste nightmare just to create a basic comparison spreadsheet.

This isn't just slow—it's incredibly risky. One misplaced decimal or a misread contract term can lock you into a bad deal, costing the company thousands.

This is where automation flips the script. An intelligent document processing tool can take in all those vendor proposals at once, no matter the layout. It instantly pulls out the crucial details:

- Unit pricing and bulk discounts

- Delivery timelines and lead times

- Payment terms and conditions

- Warranty information and compliance details

All this information is then neatly organized into a single dashboard. Your team's job shifts from 40 hours of mind-numbing data entry to one hour of smart, strategic analysis. They can see the best value, not just the lowest price, and make a decision that’s both faster and far more informed. It's one of the most powerful strategies to improve supply chain efficiency a business can adopt.

Bringing Flawless Accuracy to Finance and Accounting

In any finance department, the three-way match is the bedrock of financial control. It’s the process of confirming that the supplier invoice, the purchase order, and the receiving report all line up. When done by hand, it’s a slow, eye-straining task that clogs up the entire accounts payable pipeline.

A single mismatch—a wrong quantity or a different price—sends someone on a frustrating hunt for answers. This delays payments, wastes time, and can even sour relationships with key suppliers.

Automation makes this entire workflow instant and nearly foolproof. Here’s how it works:

- The system ingests a new invoice as soon as it arrives.

- It uses smart document parsing to read and extract all the key data.

- It then checks that data against the matching purchase order and goods receipt in your system.

- If it's a perfect match, the invoice is approved for payment in seconds. If not, it’s automatically flagged for a human to review, with the exact problem highlighted.

This does more than just speed up payments. It frees your finance pros from being data checkers, allowing them to focus on higher-value work like cash flow analysis, budgeting, and financial forecasting. To see how this works in more detail, our guide on automating data entry breaks down how this foundational step enables much more complex workflows.

Simplifying Complex Reporting in Manufacturing

Manufacturing operations often juggle incredibly complex commission structures for their sales reps. Calculating these payments means trying to stitch together reports from multiple sources, and none of them ever use the same format. A sales rep might send a spreadsheet detailing their sales, but the internal team has to manually piece it all together to figure out who gets paid what.

This manual process isn’t just slow; it's a breeding ground for errors and disputes. One simple copy-paste mistake can lead to an incorrect commission check, eroding trust with the very people driving your revenue.

Supply chain automation solves this by creating a single, reliable source of information. An automated system can pull in all the commission reports, whether they're PDFs, Excel files, or even scanned documents. It intelligently finds and extracts the data it needs—like sales volume, product codes, and customer names—and merges it all into one clean report.

The result? Fast, accurate, and completely transparent commission calculations. Reps get paid correctly and on time, every time, and managers get a crystal-clear view of sales performance without lifting a finger.

The payoff for making these kinds of changes is huge. Data shows that companies adopting AI are seeing a 15% reduction in logistics costs, holding 35% less inventory, and boosting their service efficiency by a whopping 65%. You can explore more on how AI is reshaping the field with these supply chain statistics.

Your Practical Roadmap to Implementing Automation

Getting started with supply chain automation can feel like a massive project, but it doesn't have to be. The trick is to think less about a giant, company-wide overhaul and more about solving one nagging problem at a time. It’s like building with LEGOs—you start with a solid base and add new pieces strategically. This step-by-step approach keeps things manageable and helps you see real value right from the start.

Instead of trying to automate everything at once, the smartest move is to find a single, high-impact pain point and fix it. Modern, user-friendly tools have made this easier than ever, so you don't need a huge IT budget or a team of developers to get going.

Step 1: Identify Your Biggest Bottleneck

Before you even look at software, take an honest look at your daily operations. Where does work grind to a halt? What's that one task that eats up the most manual hours and frustrates your team to no end? Chances are, it involves paperwork.

Think about how much time your team spends on things like:

- Manually typing in data from invoices or purchase orders.

- Chasing down missing information or fixing simple typos.

- Trying to compare vendor quotes that are all in different formats.

That specific, repetitive job is your perfect starting point. When you target the biggest time-waster first, you pretty much guarantee your first automation project will deliver an immediate and noticeable return.

Step 2: Start Small With a Pilot Project

Once you’ve zeroed in on your bottleneck, resist the temptation to roll out a solution to the whole company. Instead, kick things off with a small, controlled pilot project. Think of it as a proof-of-concept, giving you a chance to test the tech and your new process on a manageable scale.

For example, if invoice processing is your biggest headache, focus your pilot on automating invoices for just one department or from a single key supplier. This contained experiment makes it much easier to work out the kinks, measure your results accurately, and build a solid case study to get other departments excited.

The point of a pilot isn't perfection; it's learning. A successful small-scale test gives you invaluable insights and builds the confidence you need to scale your supply chain automation efforts effectively.

Starting small takes the risk out of the process and makes it easy to score some quick wins. To see how this works for a specific document, you can learn more about creating an automated purchase order system and see how a focused project can produce big results.

Step 3: Choose the Right Tools for the Job

With your pilot project clearly defined, it’s time to find the right tool. The market today is full of powerful, no-code platforms built for business users, not just tech wizards. Look for a solution that’s intuitive, connects easily with the systems you already use, and has a straightforward pricing model.

A platform like DocParseMagic is a great fit for document-heavy workflows because it doesn't require any complicated setup or manual template building. You can just upload your files and get structured data back in minutes. That kind of immediate usability is exactly what you need for a successful pilot.

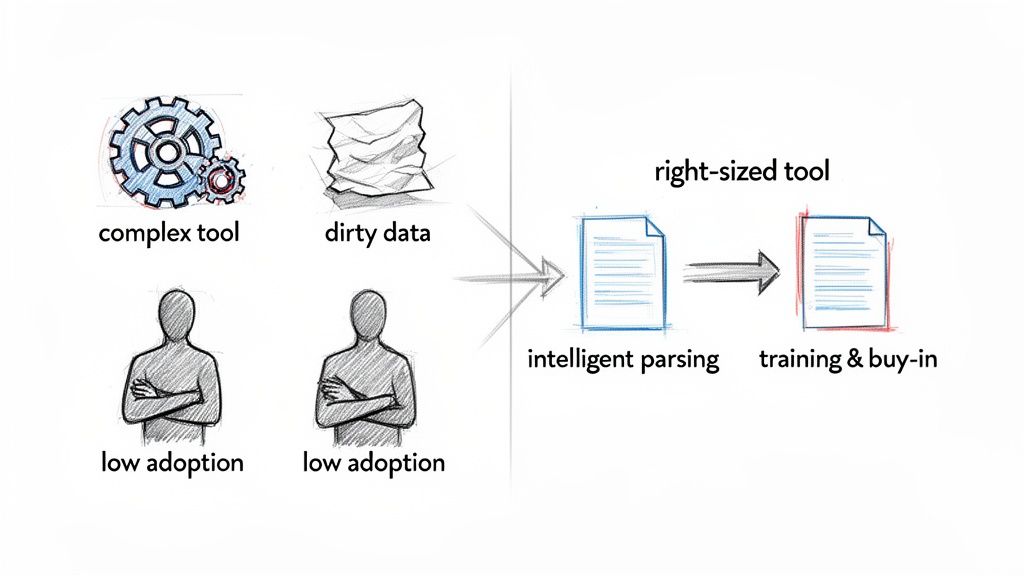

The image below shows how automation can connect and improve workflows across key departments, from procurement and finance to manufacturing.

This flow highlights how a single tool can act as a central hub, turning all sorts of unstructured documents into clean, usable data for everyone who needs it.

Step 4: Implement and Empower Your Team

Getting the tool in place is one thing; getting your team on board is another. Good training is non-negotiable. Make sure you focus on how the new tool makes their jobs easier, not just how it helps the company's bottom line. Frame it as a way to get rid of their most boring tasks so they can focus on more engaging, strategic work.

Create a few simple guides, host a quick training session, and make sure everyone knows who to go to for help. When you empower your team with the right skills and support, they become champions for the new process instead of roadblocks.

Step 5: Measure Success and Scale What Works

Finally, it’s time to look back at your pilot project and measure its impact. You’ll want to track a few clear, simple metrics that prove its value. This is where you can truly see if your efforts paid off.

How to Measure Automation Success

Tracking the right metrics is crucial for understanding the real-world impact of your automation initiatives. Here are some key performance indicators (KPIs) to monitor.

| Metric Category | KPI Example | What It Tells You |

|---|---|---|

| Efficiency Gains | Time Saved Per Task | How many hours are freed up for more valuable work. |

| Accuracy | Error Rate Reduction | The percentage decrease in manual data entry mistakes. |

| Speed | Cycle Time Improvement | How much faster a process is from start to finish. |

| Cost Savings | Cost Per Transaction | The direct financial savings from automating a workflow. |

With this data in hand, you have a powerful story to share. Use these results to justify expanding your supply chain automation efforts. The lessons you learn from the pilot will be your guide as you roll out the solution to other teams, tackling your next biggest bottleneck with a proven playbook for success.

Common Automation Pitfalls and How to Sidestep Them

Bringing automation into your supply chain can be a massive win, but it’s not a magic wand. Like any big project, it’s filled with potential traps that can sink your efforts before they even get off the ground.

Knowing what these common hurdles are ahead of time is your best defense. It helps you dodge the frustrations, budget overruns, and team burnout that plague so many well-intentioned projects. Let’s break down the three biggest mistakes and how to avoid them.

The Problem of Bad Data

This one is the classic killer of all things automation: "garbage in, garbage out." Your shiny new automated system is only as smart as the information you feed it. If you're pumping in messy, incomplete, or just plain wrong data from invoices and shipping forms, all you’ve done is build a faster way to make the same old mistakes.

And this isn't a minor issue. Even as automation is poised to take over logistics by 2026, a staggering 41% of operations leaders say they’re stuck fighting data quality fires. It’s a huge roadblock for the 53% of companies already using AI, as detailed in these supply chain trend insights.

The fix? You need a bouncer at the door of your system. An intelligent document parsing tool acts as that filter, catching, cleaning, and structuring data before it gets into your workflow. It turns chaotic PDFs and messy scans into the clean, reliable fuel your automation needs to run properly.

Choosing Overly Complex Tools

It’s so easy to fall for the "does-it-all" platform. The sales pitch is amazing, promising to solve every problem you have and ever will have. The reality? You end up with a monstrously complicated tool that costs a fortune, takes forever to learn, and is packed with features your team will never touch.

This complexity is the direct cause of low user adoption. When a tool is a nightmare to use, people will do what they’ve always done: find a workaround. They'll go right back to their old spreadsheets and manual habits, and your big investment will just sit there collecting dust.

The Solution: Start with the problem, not the technology. Pinpoint your exact pain—like hours wasted on manual invoice entry—and find the simplest, most elegant tool that fixes that specific thing. A focused, user-friendly platform almost always beats a bloated, all-in-one system.

Neglecting Team Buy-In

Last but not least, automation projects often fail because they forget about the people. If you just drop a new tool on your team without explaining the why, they're likely to see it as a threat. Is this robot going to take my job? That kind of fear leads to resistance and a project that’s dead on arrival.

Instead, you need a solid change management game plan.

- Communicate Early and Often: Frame the change as a positive. Explain that the goal is to get rid of the boring, repetitive tasks so they can focus on more important, strategic work.

- Get Them Involved: Talk to the people who are actually doing the manual work. Ask them what they need. Their insights are invaluable for choosing the right solution.

- Train, Train, Train: Give your team the hands-on training they need to feel confident and capable with the new system.

By tackling these pitfalls—insisting on clean data, picking the right-sized tools, and making your team part of the journey—you’re setting your supply chain automation strategy up for real, lasting success.

Got Questions About Automation? Let's Get Them Answered.

Whenever I talk to businesses about supply chain automation, the same handful of questions pop up. It's completely normal. Before you dive in, you need practical answers to feel confident this is the right move. Let's walk through the big ones.

This isn't just theory. We're talking about real-world effects on your budget, your team, and how you get work done every day. Getting these answers straight will help you build a smarter automation plan from the get-go.

Is This Automation Stuff Just for the Big Guys?

Not anymore. While massive corporations were the first ones on the automation train, the game has totally changed. Today, affordable, no-code platforms put incredibly powerful tools within reach for small and medium-sized businesses.

You don't need a huge IT department or a blank check. Tools that zero in on a specific, high-impact task—like parsing documents—offer a low-cost way to get started and see a surprisingly fast return. Any company, no matter its size, can start getting more efficient right now.

Will Automation Make My Team Obsolete?

This is a common fear, but the reality is quite different. The goal of supply chain automation isn't to replace your people; it's to supercharge them. Think of it as giving your best employees a tireless assistant who handles all the boring, repetitive work they hate.

This shift frees your team to focus on the things that actually require a human brain: strategic thinking, solving tricky problems, negotiating better deals with vendors, and handling the inevitable exceptions. Automation elevates their work, making them more valuable to the business, not less.

How Do I Actually Measure the ROI?

Measuring your return on investment is a mix of hard data and some softer, but equally important, benefits. The key is to get a clear "before and after" snapshot.

On the hard numbers side, you'll want to track:

- Time Savings: How many hours per week are you getting back from tasks like manual data entry?

- Error Reduction: By what percentage did you cut down on costly mistakes?

- Labor Costs: How much money are you saving on direct labor for a specific workflow?

Don't forget the softer wins, either. Think about improved team morale (no more mind-numbing work), quicker decision-making, and more reliable relationships with your suppliers.

We're on a Tight Budget. What's the Best First Step?

Start small, and aim for a quick win. Pinpoint the single biggest manual bottleneck in your process. For most businesses, this is wrestling with documents like invoices, purchase orders, or packing slips—it’s time-consuming, critical, and a perfect target for automation.

Find a simple, no-code tool with a free trial and run a small pilot project. Automating just one tedious task and showing clear time savings is the best way to prove the concept and build a case for doing more.

Ready to eliminate your biggest document bottleneck? DocParseMagic turns messy invoices, purchase orders, and reports into clean, organized data in minutes—no templates or coding required. Start your free trial and see how much time you can save at https://docparsemagic.com.