Your Guide to Automation in Supply Chain

At its core, supply chain automation is about using technology—everything from robots to artificial intelligence—to manage and improve how goods move from the factory floor to a customer's doorstep.

Think of it as giving your logistics network a highly advanced central nervous system. This system allows the entire operation to react faster, work with greater precision, and require far less hands-on effort, making your business smarter and much tougher in the face of disruption.

The New Reality of Supply Chain Operations

Picture a warehouse where robotic arms pick and pack orders with flawless accuracy. At the same time, an AI algorithm instantly reroutes a shipment to dodge a storm brewing on the other side of the planet. This isn't a scene from a sci-fi movie; it's what modern logistics looks like today.

The real goal of automation in the supply chain is to go beyond just automating simple, repetitive tasks. It's about creating a deeply interconnected system that can think for itself, adapt on the fly, and execute complex jobs with very little human guidance.

For years, improvements in the supply chain happened in small, gradual steps. But now, the intense pressure from e-commerce, ongoing labor shortages, and unexpected global disruptions have shifted automation from a nice-to-have advantage to an absolute must. It’s not just about speed anymore; it’s about building an operation that can actually handle the pressures of the modern world.

Why Automation Is No Longer a Choice

The market simply demands speed and reliability, and that has completely changed the rules. Companies still clinging to outdated manual processes are taking on huge risks. Automation tackles the industry's biggest headaches directly.

- Meeting Rising Customer Expectations: People now expect their orders to arrive incredibly fast—often on the same day—and they want to track them every step of the way. Automation in fulfillment and tracking is what makes this level of service possible on a large scale.

- Overcoming Labor Challenges: With persistent labor shortages and rising wages, automated systems step in to fill critical gaps. They can handle the physically taxing, repetitive jobs around the clock without getting tired.

- Building Operational Resilience: The world is unpredictable. Knowing how to focus on building a resilient supply chain has become essential, and automation is a huge part of that. These systems can pivot when disruptions hit, rerouting shipments and adjusting inventory levels automatically.

This shift isn't just talk; the numbers back it up. The global logistics automation market is expected to grow at a compound annual growth rate (CAGR) of 14.7% from 2024 to 2030. This boom is driven by businesses everywhere adopting these technologies to slash costs and dramatically improve how they operate.

Understanding the Technologies Driving Automation

To really get a handle on automation in the supply chain, it helps to think of the technologies behind it as a highly skilled team. Each member has a specific job, but their real power is unlocked when they work together. It's this teamwork that turns a traditional, manual supply chain into a smart, responsive network.

The Brains: AI and Machine Learning

At the head of this team, you've got the "brains" of the operation: Artificial Intelligence (AI) and Machine Learning (ML). These systems are the strategic thinkers, crunching massive amounts of data to make predictive, intelligent decisions. They don't just follow a set of rules; they learn from what's happened before, spot patterns, and forecast what's coming next.

This forecasting ability lets businesses shift from just reacting to problems to proactively planning for the future. For instance, an ML algorithm can analyze historical sales figures, current market trends, and even weather patterns to predict a surge in demand for a certain product. This allows a company to adjust its inventory well before customers even think about placing an order.

The Muscle: Robotics and Automated Systems

While AI and ML do the thinking, Robotics and Automated Systems provide the physical "muscle." These are the machines that move, sort, store, and handle goods with a level of precision and endurance that humans simply can't match. This category covers a huge range of hardware built to take over repetitive and physically tough jobs.

A couple of common examples you’ll see in warehouses are:

- Automated Guided Vehicles (AGVs): Picture self-driving carts that follow pre-set paths to shuttle materials around a facility. They effectively eliminate the need for manual forklift operators.

- Automated Storage and Retrieval Systems (AS/RS): These are towering, complex systems of racks, cranes, and shuttles that automatically put items away and grab them when needed. They're a game-changer for maximizing warehouse space and retrieval speed.

This kind of physical automation is absolutely essential for hitting the speed and scale that modern e-commerce demands. To see how these systems fit into the bigger picture, it’s worth exploring some common e-commerce automation tools and strategies.

The Senses: Internet of Things (IoT)

Finally, we have the Internet of Things (IoT), which acts as the "senses" for the entire system. IoT is a network of physical devices—sensors, cameras, and GPS trackers—that are embedded all along the supply chain. These devices collect and send real-time data about the location, condition, and status of goods and equipment.

This constant flow of live information is what connects the "brains" (AI) to the "muscle" (robotics). An IoT sensor inside a refrigerated truck can monitor the temperature of a shipment, pinging the AI if it strays from the safe zone. In the same way, RFID tags on pallets give instant inventory updates as they move, making sure the data the AI is using is always spot-on.

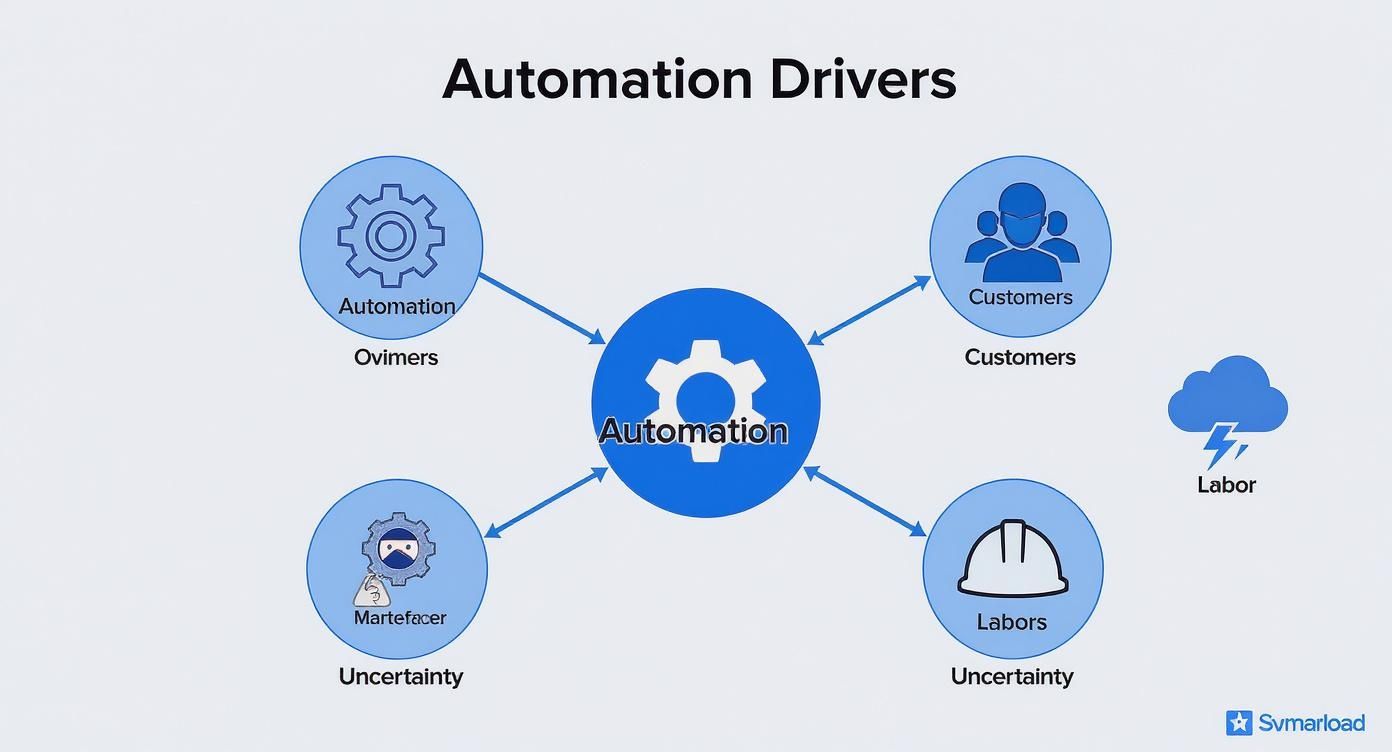

The image below shows how things like customer expectations, labor challenges, and general uncertainty are pushing companies to embrace these technologies.

This visual really drives home how outside pressures are fueling the need for a smarter, more automated supply chain.

A huge part of this data-driven approach involves handling the mountain of paperwork that comes with logistics, from purchase orders to invoices. This is where Intelligent Document Processing (IDP) comes in. IDP uses AI to automatically pull key information from these documents and organize it. To learn more about this specific technology, check out our guide on what is intelligent document processing.

To help you see how these technologies fit together, here's a quick breakdown:

Key Automation Technologies in the Supply Chain

| Technology | Primary Function (The 'Role') | Example Application |

|---|---|---|

| Artificial Intelligence (AI) & Machine Learning (ML) | The "Brains" - Predictive analytics and decision-making. | An AI system analyzes historical data, weather patterns, and social media trends to forecast demand for seasonal products. |

| Robotics & Automated Systems | The "Muscle" - Physical task execution and material handling. | An AGV transports finished goods from the production line to the warehouse without human intervention. |

| Internet of Things (IoT) | The "Senses" - Real-time data collection and monitoring. | An IoT sensor on a shipping container tracks its location, temperature, and humidity, sending alerts if conditions change. |

| Intelligent Document Processing (IDP) | The "Translator" - Extracts and structures data from documents. | An IDP tool automatically scans incoming invoices, extracts key details like amounts and due dates, and enters them into the accounting system. |

As you can see, each piece of the puzzle has a clear role, but they are far more powerful when they work in sync.

The combined impact of these technologies is massive. The global supply chain automation market is on track to hit $128.3 billion by 2030. This explosive growth is a direct result of how effective these tools are at managing everything from orders to inventory, boosting accuracy, and cutting down the need for manual work.

When you put it all together, these technologies create a powerful feedback loop. Data from IoT sensors informs AI-driven decisions, which then guide the actions of robotic systems. This seamless flow is the foundation of a modern, resilient, and truly automated supply chain.

The Real-World Benefits of an Automated Supply Chain

It’s one thing to understand the tech behind automation, but it’s another to see the real, tangible results it brings to the table. Bringing automation into a supply chain isn't just about a technical upgrade; it's a strategic overhaul that changes the very way a business operates. The positive effects ripple through the entire organization, from the warehouse floor right up to the bottom line.

These aren't just empty promises. Survey data from 2024–2025 highlights a massive shift, with around 50% of large companies planning to pour serious money into AI and IoT for their supply chains. The numbers speak for themselves—companies that make the leap see logistics costs drop by roughly 15%, inventory levels shrink by 35%, and service efficiency shoot up by an incredible 65%. You can dig into more of this data on AI adoption in supply chains at erbis.com.

Drastically Reduced Operational Costs

One of the first and most powerful impacts you’ll notice is a serious drop in operational expenses. Let’s face it, manual processes are expensive. They’re burdened by labor costs, the high risk of human error, and countless small inefficiencies that bleed resources over time.

Automation goes right after these costs. Think about it: robotic systems in a warehouse can run 24/7 with minimal oversight, which immediately slashes the labor cost tied to each order. They also pick and pack with near-flawless accuracy, meaning fewer expensive mistakes like shipping the wrong product or miscounting inventory.

This precision also extends to administrative work, where many businesses find hidden savings. For instance, looking into automated invoice processing software shows how you can eliminate manual data entry errors and get paid faster.

A Massive Boost in Efficiency and Speed

In today's market, speed is the name of the game. Automation acts like a turbocharger for every link in the supply chain, from the moment goods arrive to the final delivery. Automated systems don’t get tired, don't need breaks, and perform tasks at a pace that people simply can't sustain.

Picture a fulfillment center. An Automated Storage and Retrieval System (AS/RS) can find and grab an item in seconds—a job that might take a human worker several minutes. This translates directly to:

- Faster Order Fulfillment: Orders fly out the door much more quickly, helping you hit those tight delivery deadlines.

- Shorter Lead Times: Automating everything from procurement to production shortens the entire cycle, getting your products into customers' hands faster.

- Higher Throughput: Warehouses can suddenly handle a much larger volume of orders without needing to build an extension or hire more people.

"By automating repetitive and physically demanding tasks, businesses can reallocate their human workforce to more strategic roles. This not only optimizes labor but also empowers employees to focus on problem-solving, customer service, and overseeing the automated systems themselves."

This change doesn't just improve operational speed; it boosts team morale and engagement, too.

Unmatched Accuracy and Reliability

No matter how skilled your team is, human error is an unavoidable part of any manual system. From a simple miscount of inventory to a mislabeled shipment, these small mistakes can snowball into big problems like stockouts, unhappy customers, and wasted money.

Automation brings a level of precision that practically eliminates these issues. Systems using barcode scanners, RFID tags, and computer vision make sure every single item is tracked perfectly from the second it enters the warehouse to the moment it leaves. Your inventory data becomes rock-solid and always up-to-date, giving you a reliable foundation for making smart decisions.

This reliability goes beyond just counting boxes. Automated quality control systems can inspect products with far greater accuracy than the human eye, catching tiny defects early. This ensures that only top-quality products reach your customers, which protects your brand's reputation and cuts down on the costs of handling returns.

How Top Companies Win with Supply Chain Automation

The theory behind supply chain automation is one thing, but seeing it in action is where you grasp its real power. The world’s biggest companies aren’t just dabbling in these technologies—they’re building their entire operations around them to create a serious competitive advantage.

These leaders aren't using automation for its own sake. They're pinpointing specific, high-stakes problems and applying targeted automation to solve them. Let's look at a few powerful examples of how this delivers real, measurable results.

E-Commerce Giant Masters Same-Day Delivery

One of the world's largest online retailers was facing a problem born from its own success: how to deliver on a same-day delivery promise for millions of customers. Their massive warehouses, staffed with human pickers walking up and down endless aisles, just couldn't move fast enough. This bottleneck was putting customer satisfaction—and future growth—at risk.

The answer was to bring in a fleet of Autonomous Mobile Robots (AMRs). Instead of workers covering miles of concrete each day, these robots bring the shelves directly to the workers.

- The Solution: AMRs expertly navigate the warehouse floor, find the right shelving unit, and shuttle it to a stationary packing station.

- The Impact: This “goods-to-person” model completely changed the game. It eliminated the time workers wasted just walking, which was a huge drain on productivity.

- The Result: Order fulfillment times were slashed by more than 50%. Warehouse throughput doubled during busy seasons, and picking accuracy shot up to nearly 100%. This single move was the key that unlocked their ability to consistently hit that ambitious same-day delivery target.

By automating the most physically demanding and time-consuming part of the job, the company turned its fulfillment centers from a logistical headache into a massive strategic weapon.

Global Food Company Protects Its Cold Chain

For a global food and beverage company, temperature is everything. Their "cold chain"—the refrigerated supply line for perishable goods—was a constant source of anxiety. One broken cooling unit or a simple delay could mean spoiling thousands of dollars worth of products, creating huge waste and even safety risks.

To fix this, the company built a smart, self-monitoring cold chain using the Internet of Things (IoT) and AI.

They placed IoT sensors inside their refrigerated trucks and storage facilities to track temperature, humidity, and location around the clock. All of this data feeds into a central AI-powered dashboard that constantly scans for anything out of the ordinary.

Now, if a truck’s refrigeration starts to fail or a door is left ajar, the logistics team gets an instant alert. The AI can even predict when equipment might fail by analyzing its performance over time. The impact was immediate.

- Measurable Reduction: The company cut its losses from spoilage by over 30% in the first year alone.

- Enhanced Compliance: They now had a perfect, verifiable log of temperature data, making regulatory compliance a breeze.

- Proactive Management: They went from reacting to disasters to preventing them from ever happening.

This wasn't just about saving money; it was about protecting their brand and keeping their customers safe.

Logistics Provider Delivers Unmatched Transparency

A leading third-party logistics (3PL) provider was stuck in a crowded market where efficiency and trust are the only things that matter. Their old manual methods for managing freight—picking carriers, tracking shipments, filing customs paperwork—were slow and full of errors. Worse, their clients were left in the dark.

Their solution was to build a fully automated freight management system. This platform pulled every part of their transportation logistics into a single, intelligent system. Now, AI analyzes carrier rates, routes, and performance to automatically pick the best option for every single shipment, perfectly balancing cost and speed.

Once a package is out the door, integrated GPS and IoT data feed into a live tracking portal, giving clients a real-time view of their shipment from start to finish. The system even handles the complex customs documentation automatically, eliminating what was once a huge source of delays.

The wins were clear and immediate:

- Optimized Costs: The automated carrier selection cut freight spending for their clients by an average of 12%.

- Superior Service: Real-time tracking and automatic updates made for much happier customers who stuck around.

- Increased Efficiency: The team cut time spent on administrative busywork by 75%, freeing them up to focus on strategy and building client relationships.

By fully committing to automation, this 3PL turned its logistics service from a simple commodity into a high-value, transparent partnership.

Your Roadmap to Implementing Automation

Diving into supply chain automation can feel like a monumental task, but it doesn't have to be. The secret is to approach it as a journey of deliberate, well-planned steps—not a single, giant leap. A solid roadmap turns a complex project into a manageable process, making sure every decision builds on the last and delivers real value.

Think of this not as a technical manual, but as a strategic guide for any business ready to get started. By following a structured path, you can demystify the process, get your team on board, and set your company up for long-term success.

1. Assess and Identify Your Starting Point

Before you can build the future, you need a crystal-clear picture of the present. The very first step is a thorough audit of your current supply chain. Think of it as creating a detailed map of your operations, highlighting all the smooth roads, frustrating bottlenecks, and hidden weaknesses.

Your goal here is simple: find the friction. Where are manual tasks causing the most errors? Which processes are eating up the most time and labor? What delays are causing headaches for your customers? These pain points are your prime candidates for automation.

Start by looking for high-impact, low-complexity opportunities. For example, manual data entry for purchase orders is a classic resource drain and a frequent source of costly mistakes. Automating just this one process can provide an immediate and noticeable return. Our guide on automated purchase orders offers a deeper look into this specific win. By targeting these clear opportunities first, you prove the value of automation right out of the gate.

2. Start Small to Scale Smart

In supply chain automation, the "go big or go home" approach is a recipe for disaster. A far more effective strategy is to begin with a focused pilot project. This small-scale test run acts as your proof of concept, letting you validate the technology, measure the return on investment (ROI), and learn critical lessons in a low-risk environment.

A great pilot project targets one of the specific pain points you found during your assessment. You might implement a simple RFID tracking system in one corner of your warehouse or automate a single, mind-numbing administrative task.

The goals for your pilot should be incredibly clear:

- Prove ROI: Show tangible benefits, like a 15% reduction in picking errors or a 20% decrease in order processing time.

- Gain Buy-In: Use the positive results to build excitement and support from stakeholders and the rest of the team.

- Identify Challenges: Uncover potential integration hiccups or training gaps before you commit to a full-scale rollout.

A successful pilot is your most powerful tool for building momentum. It transforms the abstract idea of "automation" into a concrete success story everyone in the organization can see and understand.

To help you decide where to begin, consider which area aligns best with your immediate goals.

Automation Implementation Focus Areas

| Automation Area | Primary Goal | Key Technologies Involved | Best For |

|---|---|---|---|

| Back-Office Processes | Reduce administrative overhead and errors | Document automation (OCR), RPA | Businesses bogged down by manual data entry, invoicing, and order processing. |

| Warehouse Operations | Increase speed, accuracy, and throughput | WMS, RFID, ASRS, AGVs | Companies with high-volume fulfillment and inventory management challenges. |

| Transportation & Logistics | Improve visibility and optimize routes | TMS, GPS tracking, AI-powered route planning | Organizations looking to cut fuel costs, improve delivery times, and track shipments in real-time. |

| Demand Forecasting | Enhance accuracy and reduce stockouts | AI, Machine Learning, Predictive Analytics | Businesses in volatile markets needing to better align inventory with customer demand. |

Choosing a pilot from one of these areas allows you to concentrate your resources and demonstrate value quickly, which is key to getting the green light for broader implementation.

3. Choose the Right Technology Partner

Selecting the right technology and vendor is one of the most important decisions you will make. The market is crowded with options, from niche software tools to massive robotic systems. Your choice shouldn't just be about the tech itself, but about the partner standing behind it.

Look beyond the initial price tag. A true partner will take the time to understand your specific business challenges and goals. They should be able to provide case studies from businesses like yours, proving they have a track record of delivering results.

Keep these essential criteria in mind:

- Scalability: Can the solution grow with your business? Don't get locked into a platform you'll outgrow in a year.

- Integration: How well does the technology play with your existing systems, like your ERP or WMS?

- Support and Training: What kind of support does the vendor offer during and after implementation? Great support is non-negotiable.

4. Manage Change and Train Your Team

Finally, never forget the human element. The success of automation in your supply chain depends just as much on your people as it does on the technology. New systems will inevitably change daily routines and job descriptions, and it's vital to manage this transition with transparency and care.

Start by clearly communicating the "why" behind the change. Explain how automation will eliminate tedious, repetitive work, freeing up employees to focus on more strategic, high-value tasks. Frame automation not as a replacement, but as a tool that empowers your team to be more effective.

Invest heavily in training. Provide comprehensive, hands-on education to make sure everyone is comfortable and proficient with the new tools. This not only guarantees a smooth operational transition but also shows your team you are investing in their growth. A well-prepared team is an enthusiastic team, ready to embrace the future you're building together.

Got Questions About Supply Chain Automation? We've Got Answers.

It's one thing to read about the benefits of automation, but it’s another thing entirely to start planning for it. When you start digging in, real-world questions pop up. Concerns about the price tag, what it means for your team, and the headaches of getting it all running are completely normal.

Let's cut through the noise and tackle these common questions head-on. The goal here is to give you honest, practical answers that will help you make the right call for your business.

How Much Is This Going to Cost?

This is always the first question, and the only honest answer is: it really depends. There's no one-size-fits-all price for automation in the supply chain. The investment is tied directly to what you're trying to do and the tech you choose.

Think of it on a spectrum.

On one end, you have software. This is often the easiest place to start. A subscription for an automated inventory system or an invoice-reading tool might run anywhere from a few hundred to a few thousand dollars a month. It’s a predictable operating expense and a much lower bar to clear.

On the other end is the heavy machinery. We’re talking about robotics—like Automated Guided Vehicles (AGVs) zipping around a warehouse or a full-blown Automated Storage and Retrieval System (AS/RS). These are major capital investments, easily running into the hundreds of thousands, if not millions, of dollars.

But here’s the most important shift in thinking: stop seeing it as just a cost. Frame it as a Return on Investment (ROI). A good automation project should pay for itself by cutting labor costs, slashing expensive errors, and making your whole operation more productive. Do the math—weigh the total cost against what you stand to save and gain. That’s where you'll find the true financial picture.

Will Robots Take Everyone's Jobs?

This is a big one, and it’s wrapped up in a lot of misconception. The goal of supply chain automation isn't to replace your people; it's to redefine their jobs. It’s less about eliminating roles and more about elevating them.

Automation is perfect for the repetitive, back-breaking, and mind-numbing tasks that people frankly aren’t great at over the long haul. A robot can lift heavy boxes all day without getting tired. Software can process thousands of invoices without a single typo. This frees up your team to focus on things machines can't do: critical thinking, creative problem-solving, and managing customer relationships.

You'll see a shift in roles:

- From Manual Laborer to Robot Technician: Instead of hauling pallets, an employee is now in charge of a fleet of AGVs, keeping them running and optimizing their routes.

- From Data Entry Clerk to Data Analyst: Instead of typing in order details, that same person is now analyzing the data pulled in by the automated systems, looking for ways to make things even more efficient.

This evolution creates better, more engaging jobs. Your workforce becomes more skilled, and their work becomes safer and more valuable to the company.

What Are the Biggest Headaches During Implementation?

While the payoff is huge, getting there isn't always a walk in the park. Knowing the common hurdles ahead of time means you can plan for them and save yourself a lot of grief.

Data Integration

This is often the first big roadblock. Automated systems need clean, organized, and accessible data to work. If your inventory data is in one system, your sales data in another, and your shipping info is stuck in a spreadsheet, getting them all to communicate can be a massive project in itself. You absolutely need a unified data strategy before you flip the switch on anything.

Change Management

People are creatures of habit. Bringing in new technology and changing the way things have "always been done" can cause friction. If you don't communicate clearly and train your team properly, you'll meet resistance. A successful rollout means getting your people on board from day one. Explain the "why," show them what's in it for them, and invest in great training to build their confidence.

Trying to Boil the Ocean

Another classic mistake is trying to do too much, too fast. Going for a "big bang" implementation where you automate everything at once is incredibly risky and often ends in failure. The smarter move is to start small. Pick one specific problem, run a pilot project, and prove the value. This lets you learn, adapt, and build momentum for bigger changes down the road.

Ready to eliminate the tedious, error-prone task of manual data entry? DocParseMagic uses AI to pull structured data from invoices, purchase orders, and other documents directly into a spreadsheet in seconds. Reclaim hours of your team's time and ensure your data is always accurate. Try DocParseMagic for free today!